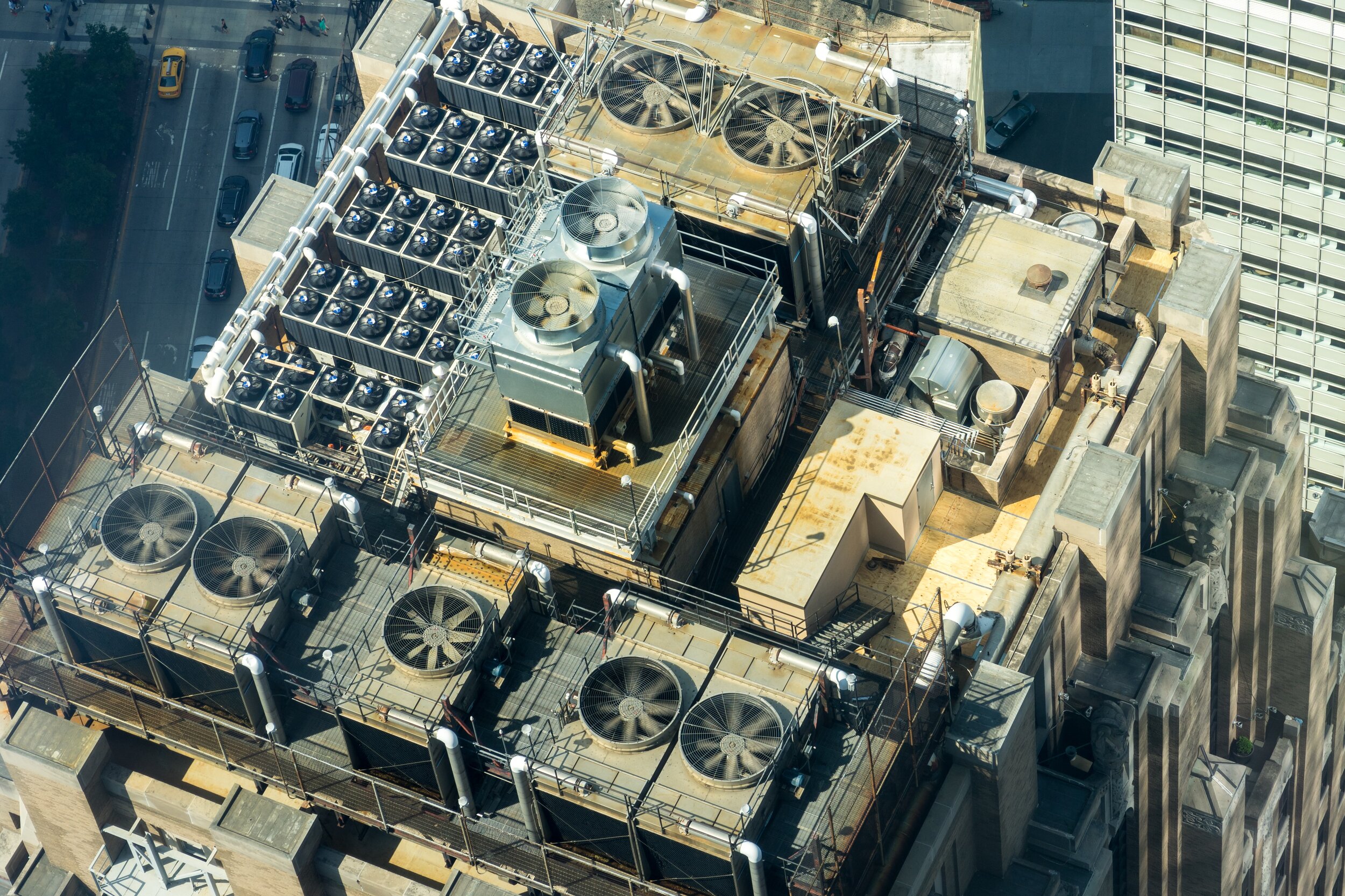

The mechanics of maxing out efficiency.

Ventilating and conditioning the indoor environment are one of the largest energy consumers for most facilities, if not the largest.

Process heating and cooling and compressed air are the other major energy consumers for most industrial customers. By modifying or replacing those energy systems, you can reduce your energy use while improving the performance of those systems which should improve your top line.

Maximize efficiency upgrades for the following:

Heating, Ventilating & Air-Conditioning (HVAC) Systems

Energy Recovery Systems

Chillers & Chilled Water Systems

Thermal Energy Storage (TES)

Boilers

Steam & Hot Water Systems

Combined Heat & Power (CHP)

Energy & Building Management Systems

Furnaces

Heat Recovery

Reactive Thermal Oxidizers (RTO)

Compressed Air Systems

Water Supply & Distribution Systems, Reverse Osmosis Systems

Wastewater

Variable Frequency Drives (VFD)

Building Commissioning

Testing, Adjusting, & Balancing (TAB)

Project Funding

The goal is always finding a net-positive funding structure. From Goverment funded programs to EeaS programs, funding is no longer an obstacle to making important energy efficiency upgrades.

Mag Max Energy Audit

Multiple integrated facility surveys. One comprehensive Investment Grade Audit.

Case Studies

With five decades of experience building and engineering facilities, we know a thing or two about optimizing them for maximum profitability, productivity, and sustainability. Check out some of our recent projects.